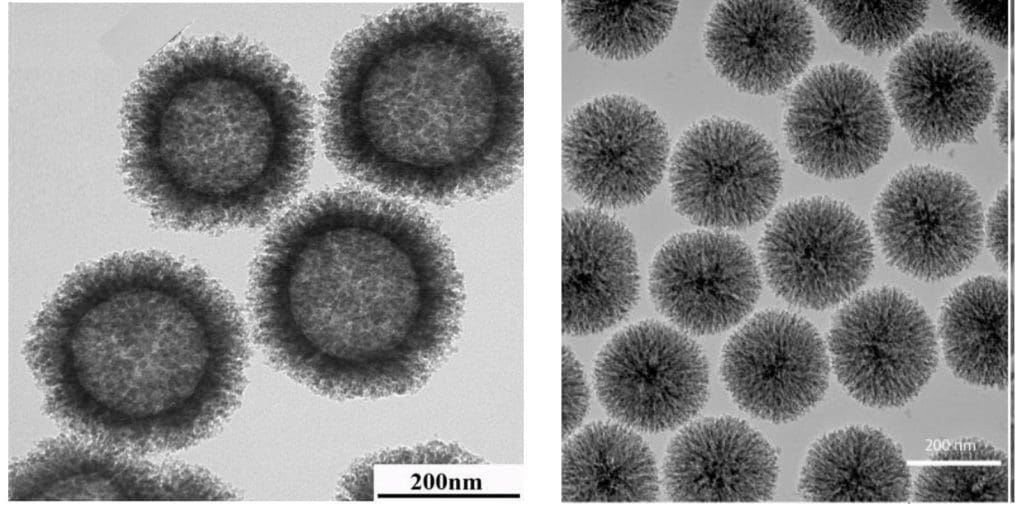

Microscopic images of the silica-based nanoparticles. Photo – UQ.

FLYSTRIKE and lice chemical delivery via tiny hollow nanoparticles less than a thousandth of a millimetre across has the potential to boost the arsenal of Australian sheep producers battling the costly conditions.

Senior research fellow Dr Peter James from UQ’s Centre for Animal Science is heading the nanotechnology project that could be part of the solution to problems estimated to cost the Australian sheep industry more than $400 million a year.

The Australian Wool Innovation-funded project is designing and testing unique silica nanocapsule particles with surface spikes purpose-built to give prolonged periods of protection against flystrike and lice.

“New methods that can provide longer periods of protection are required to counter the development of resistance to flystrike insecticides and to support the reduced reliance on mulesing, a surgical technique that has been relied upon over many years,” Dr James said.

UQ senior research fellow Dr Peter James

But Dr James does not see the technology as removing industry pressure to develop flystrike-resistant sheep.

“Flystrike control needs an integrated approach; you are going to need them all and if you’ve bred resistance in your sheep, it’s a bit like mulesing, it’s there forever, whereas this lasts longer, but not forever.”

The technology shows promise in increasing the effective control period and reducing the number of treatments needed for control. But sheep producers should not expect commercialisation of a product anytime soon, with pen, field and safety trials yet to be funded.

“We’ve had very promising results during testing with the slow-release formulations giving extended periods of protection in comparison with more conventional formulations,” Dr James said.

The researchers have been studying the use of nanocapsules to absorb and deliver currently available flystrike and lice chemicals and then attach to wool, flies or fly larva for extended targeted control. A method for loading the particles with chemicals has been developed.

Dr James said the results showed the careful choice of active ingredient can ensure minimal residues or off-target effects for the sheep.

“Nanocapsules offer new, labour-efficient options for managing flystrike and could also help counter the risk of blowflies developing resistance to treatment.

“Historically, chemical pesticides have been delivered in relatively large doses to achieve extended protection, but in slow-release formulas doses can be smaller,” he said.

“By using nanocapsules, the chemical can either be delivered at steady levels over a prolonged period or designed to release only when needed.”

Materials scientist Professor Michael Yu said UQ had patented the silica nanoparticles that feature a hollow cavity and a porous silica shell. The silica particles break down to dust and release chemicals over time.

“We’ve tested a number of designs, but the most promising is a nanoparticle that has whisker-like spikes which cover the outer surface,” Professor Yu said.

“These spikes help the capsules ‘stick’ to either the fleece fibres or to the blowflies.”

Dr James said the chemical-loaded nanocapsules have been tested in the lab on wool with fly larvae, but pen trials with larval implants are needed to test the mechanism further.

“We’ve done some work where we’ve treated the sheep, taken the wool off and inside and compared the protection that we got of that wool against the maggots in the lab – and we get an extended period of protection (the larvae died) compared to other formulations.

“In all the tests that we’ve done, we get extended periods of protection with our spiky surface nanoparticles.”

Dr James sees potential for the nanocapsule system to manage breech and body flystrike, and using the current methods of chemical application such as backline, pour-on or spray delivery. The technology worked with available organic and water-soluble chemicals, and a natural plant extract.

“One of the real advantages that we see for this is that with chemical resistance developing and the diminishing armoury of pesticides that we might be able to use chemicals that unformulated don’t last long enough to be practically useful.

“But if we put them into this formulation we can extend them, so we might be able to use chemicals that we know kill larvae, but break down quickly because of photo-degradation due to sunlight or washing out by rain.”

AWI general manager research Dr Jane Littlejohn has welcomed the research and said “nanotechnology has the potential to increase the range of treatment options available to wool growers.”

Dr James is on the right track when he speaks about the need to breed fly-proof sheep.

Those who have followed the genetic solution to breeding sheep that are fly-proof have been enjoying the benefits for many years. Given the time to develop the new nanotechnology and have it in use, the job could have been done by using a genetic approach.

What is clear is that AWI is determined to hold on to the wrinkly, fly-prone Merino and will do everything possible to keep it like that. Whilst this approach is taken, we can expect a further exodus of people from the Merino industry.

All this is so sad, as the benefits of the plain-bodied Merino with its high fertility, high survivability along with their shearability, being non-mulesed and no need to jet is being missed by so many.

It is time that AWI got behind this approach as time is running out.

Very true and well explained Jim. Like you, I can’t believe we are wasting money on this type of research.

The research has been done, as you say, by the late Dr Jim Watts, and I have been fortunate to buy into a flock which Jim classed for 20 years. I have continued to progress with Jim’s research and what he taught for the last seven years and I can honestly say: what is flystrike? We just don’t get it and our sheep are under enormous pressure in north-eastern NSW with high rainfall and high humidity conditions; the perfect recipe for bacterial growth. I repeat what Jim has already said: breed the hard collagen out of the skin and have a thin wrinkle-free skin with high follicle density and guess what no more flies.

There are any number of producers that worked with Dr Jim watts and could testify of the same experience that we are enjoying, six monthly shearing, in excess of 130 percent lambs weaned to ewes joined, high carcase yields due to light skin, not to mention high muscle value. The children don’t spend their Summer holidays treating fly-blown sheep. We want them to come back to the farm. All as a result of a light skin which requires less energy to maintain, leaving energy to be distributed to these other areas and the list goes on.

Let’s hope we start as an industry to see sense and instead of spending money on unnecessary research and use the evidence we have that is proven without a doubt thanks to Dr Jim Watts.

Well said Jim.

I can’t believe what I am reading. I have to admit, Australian Wool Innovation, you are consistent; another wasted research project.

When are you going to research stuff we need? How much money is being spent on this project? Who is responsible for steering our hard earn funds into this project? Please, stop trying to prop up the traditional wrinkly sheep and let the industry move forward.

You have tapped into research facilities (electron microscope) and research scientists that obviously are very capable. Yet, you continue to completely waste grower levies on research projects we don’t need. With the advent of electron microscopes, research can be catapulted forward to a whole new level.

As a wool grower, I am trying to take the scratchiness/prickle factor out of wool, not put more in and I quote: “the most promising is the nanoparticles that have whisker-like spikes which cover the outer surface,” Professor Yu said. Phrases like “chemical-loaded nanoparticles”. The European retailers selling next-to-skin wear and women’s apparel will love this stuff. Give us a break AWI.

The reliance on chemicals has to stop. We know that Lucilia Cuprina, the green blowfly, emerges from the ground when the soil temperature rises above 20 degrees Celsius, if moisture is present. We know what attracts Lucilia Cuprina to sheep; desirable odours. We know what causes those desirable odours; bacteria growing in the stagnant moisture trapped in the wrinkles. Ask Narelle Sales of NSW DPI.

The wrinkles are caused by the presence of hard collagen in the skin in the developing foetus in utero. Breed the hard collagen out of the skin and you will fly-proof the Australian sheep flock, and as a small bonus, you will get more lambs and you won’t have to mules. The genetic solution, given to us by the man some regarded as the most hated man in the wool industry; the late Dr Jim Watts, whom I held in high regard.

You can keep throwing chemicals and research dollars at this problem, but one has to take notice of people like UQ senior research fellow Dr Peter James’ who commented that he “does not see the technology as removing industry pressure to develop fly strike-resistant sheep.” Hence the genetic solution.

Lingering moisture in the warmer months is the catalyst for sheep to becoming fly-blown. Without the hard wrinkle the sheep has an extraordinary ability to generate heat and dry itself quickly, but it can’t dry out the lingering moisture in the hard wrinkles.

As I have said above, moisture is the problem. There is another source of moisture and that is suint or sweat glands that produce desirable odours and moisture to keep cool, which then attract our unwanted blowfly. These glands are what make humans stink as well. Sweat glands only come with primary fibres. Large primary fibres (coarse hair) and large sweat glands are a problem.

And what is the telltale sign for active sweat glands? Yellow wool. Get rid of the wrinkle and keep your wool white. We can fly-proof the Australian sheep flock. It’s that simple. AWI, stop wasting grower levies on research we don’t need.

I put my name forward to try and get on the AWI board for this exact reason. To try to direct the research dollar in the right direction. The mulesing debate started in 2005. I wonder if growers will be still breeding sheep that need to be mulesed in 50 years’ time? To fix footrot, you sell the affected sheep and don’t buy any more. To eradicate fly-blown sheep you sell the infected sheep and only buy the right-skinned rams with white wool.