LOW bale return figures for crossbred and composite clips have led to prime lamb producers questioning the importance of wool in their enterprises, with some discussing cutting ewe fleece coverage to reduce shearing and crutching frequency.

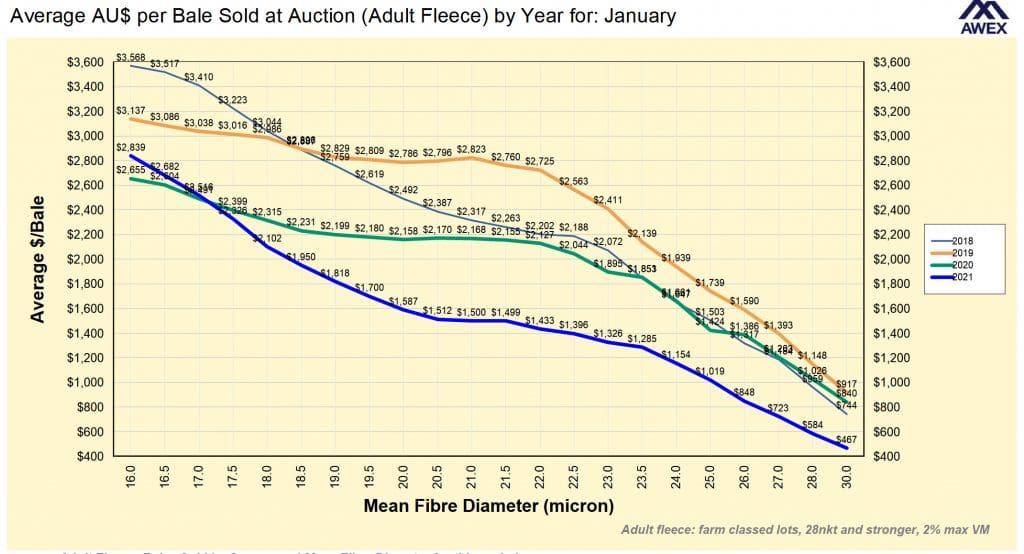

The Australian Wool Exchange has released a graph showing that gross returns for 28 micron and coarser clips slumped below $600 a bale in January this year and returns are even lower for 32 micron-plus clips.

Brokers have reported prices for 32-micron plus composite clips dropping to around 100c/kg greasy for fleece wool and returning under $200 a bale at auction, while superfine 15 micron Merino clips are making $3000 a bale.

“The difference has stretched like never before,” one broker said.

To this market background and with likely increasing shearing costs, and especially for heavy sheep, some commercial prime lamb producers are discussing how to take the wool off their ewes to limit shearing and crutching frequency, and focus more intensely on sheep that partition energy more profitably into reproduction and meat production.

Primeline and Poll Dorset ram breeder Tom Bull said as a prime lamb seedstock and commercial producer, shearing is a husbandry cost. His Primeline sheep grow 31-32 micron fleeces and his rams service more than 500,000 ewes annually.

“We have had 25,000 ewe lambs average probably $275 (in lamb return) last year and lambs making $8.20/kg this week, so you’ve got a lot of ewes producing $300 worth of lambs.”

“I’m not a big optimist for the wool job with the market dominance of one player.”

He said with returns per ewe the best they’ve been and he equates trying to improve wool returns in a prime lamb flock rather increasing meat production as “chasing your tail.”

Mr Bull said his sheep could be selected to lower fibre diameter, but with very clear gains coming from sheep meat advances, he saw no guarantees in doing this by compromising meat production.

“I’m keen to invest in the component of our enterprise that we see a lot of future in – which is meat.”

He said his future selection would focus more on meat and less on wool. Mr Bull said many of ram clients would love to be getting more for their wool.

“For anybody who understands the economics, it’s not a big worry for them.”

Will taking the wool off the points help?

Prime lamb rams with bare legs and bellies.

Sheep consultant and Lambs Alive program founder Jason Trompf said the low crossbred wool returns has increased interest among producers in cleanskin or shedding sheep, and in selecting to minimise wool on their composites, especially around the breech, belly and legs.

“They want to build a sheep that is much barer breeched and barer on the points, so there is less need for crutching and less need to shear them annually.

“So you would shear them less often or possibly every 18 months or so because their wool production and their staple length is so low that with some of the genotypes you could probably shear them once every two years,” he said.

“There are multiple farmers I’m talking with at the moment who are looking at addressing this issue by designing an animal that can be shorn in a cradle and has no belly wool and none on the points.”

Could ewes like this be shorn less than once a year?

Mr Trompf said at the moment there are higher performing carcase and reproduction genetics in the woolled composites than in the shedding composites.

“They are looking at breeding a lower wool-orientated composite.”

Mr Trompf said “sharp” composite flock owners are observing that on a meat production per hectare basis, the animals that are partitioning less resources to growing wool and more to carcase and reproduction are more productive on a per hectare basis.

“So yes, they are not making the money out of the wool and there is that ongoing and potentially rising cost of harvesting low value wool, but they are also noticing that the animals that are producing less wool are more productive on meat per hectare basis.”

He said at the moment many of the composites had too much wool to eliminate an annual crutch, but many composites with little or no wool on the bottom third of their body do not need to be crutched.

“To breed a composite where you are increasing wool value it is a significant choice and it is a trade off against other aspects of your breeding objective.

“Some breeders are doing that, but you’ve got to keep a close eye on the total productivity of the animal and make sure you are not lifting fleece value and going backwards in other areas.”

‘No-one is buying farms with crossbred wool’ – Keiller

Cashmore Composite seedstock producer John Keiller said his 34 micron wool sold recently for around $191 per bale with fleece at 110c/kg a greasy.

He said wool’s percentage contribution to a prime lamb enterprise’s gross income has always been low.

“The thing is on a property like this you can put off B-double after B-double load of lambs at $100,000 a truck load and you would put a B-double load of wool out and it’s worth $30,000.

“No-one is buying farms with crossbred wool and no-one has bought farms with crossbred wool for a long time.”

Mr Keiller said his cleanskin Nudies flock is making $8/ewe mated annual genetic improvement compounding – more growth, more lambs, less parasites, better carcase.

“Just the big things that make you money, so if you get all your ducks in a row, cleanskin sheep are interesting.”

Mr Keiller said the issues in the next 12 months will be the scarcity of shearers, with shearing rates likely to go up, and low wool and skin prices.

“It’s getting down to the stage that it (coarse wool) might just be a little boutique industry – if you want to call carpet a boutique industry.”

Mr Keiller said he had noticed interest among ram buyers for rams with bare breeches not requiring crutching.

“People haven’t moved to the stage of using breeding values to reduce wool, I don’t believe, or not very many people have.

“And the white line they need to cross is that they need to think about shearing not on a calendar-based system but on an as needed basis system,” he said.

“There are other people in the wool harvesting system that work on an annual cycle.

“You are going to need a contractor with a flexible work plan.

“We’ve got all these traditional mores, values, systems and processes that are holding back the economic returns.”

He said some flock owners are talking about trying to drop a shearing, “but I haven’t seen it happen.” Shearing a composite ewe flock would also have consequences for joining and other management issues.

Mr Keiller said only a few composite ram buyers complain about their wool returns.

“They certainly large value in the type of sheep that they run and if they have to take a loss in the wool area, that is being absorbed within the system, so we are talking about systems productivity rather than specifics productivity.

“They are still picking up something for skins and keeping themselves in the market in case it does turn.”

Some work to be done in the broad micron area

National Council of Wool Brokers of Australia executive director Chris Wilcox said the market demand for 32 micron and broader wool has been low globally for the past four years and the quantities are increasing with changes in flock composition.

“And even though the price relativity with say polyamide (synthetics) has been low for a long time, there are no real signs of improving demand.

“I’m concerned that there has been a structural change to demand for that (32-micron) wool and particularly for carpet types,” he said.

“Polyamide has just taken it and wool is just not getting a look in and without having a new product like we have in Merino wool and superfine wool for next-to-skin and sportswear, it is going to struggle.”

He said there were different markets for the 28-32 micron wool, that goes into the overcoat, double-face fabric, fake fur and upholstery products, which had only struggled recently.

Mr Wilcox said there was a need for more research, development into products markets for 32 micron-plus wool.

“There does need to be some work done in that broader micron area.”

Interesting comments. The shedding breeds have an open breeding season, so it’s not unrealistic to lamb every eight months. Yes, they don’t have the estimated breeding values of the British breeds, but at 1.5 lambs per year plus multiples, maybe they don’t need to.