WET conditions and hot temperatures are often the signals to keep an active eye out for flystrike, and getting ahead of the game makes good sense.

Along with remaining vigilant, it also pays producers to ensure they have the right equipment and chemicals to deal with any issues as they arise.

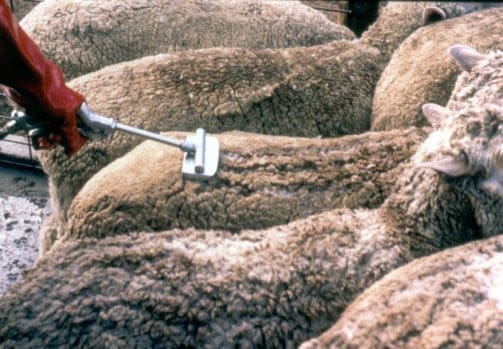

While larger producers can use a race or dip to apply chemical treatments, hand jetting has regained popularity for smaller operators or those needing some flexibility to treat in multiple areas of the property.

Brisbane-based Megajet Power Equipment has been manufacturing jetting and spray machines for over 40 years, and owner Gavin Crocker said he received a growing number of inquiries in recent months.

“Over the past few weeks, we have seen a surge in interest, and in talking to outlets like Nutrien Ag Solutions and Elders, it appears that they are having difficulties in sourcing local equipment, so the demand is there at the moment.”

Mr Crocker said there are plenty of benefits to considering hand jetting as a viable option for producers.

“When it comes to chemical use, the advice from government advisory staff is that correct hand jetting, although time-consuming, is the most thorough method of application, maximising the benefit of the treatment being applied.”

“In addition to a better application, a hand jetter at $3,500 represents cost-effectiveness, particularly compared to the tens of thousands of dollars for an automatic jetting race.”

Mr Crocker said his three decades of experience in producing hand jetting equipment meant producers could get a solid, reliable and cost-effective setup to suit their needs.

Megajet uses Italian-manufactured Comet diaphragm pumps coupled with reliable Honda 6.5hp petrol engines. This combination produces a setup delivering consistently strong pressure and throughput, with the ability to run two guns at once if required.

“The benefit of our approach is not just the equipment but also the time taken to set everything up.”

“We pride ourselves on delivering to meet the needs of our customers. We set things up with the hand pieces for sheep jetting, and we can also supply the right hoses and other gear so that once it arrives, it can be put to work.”

Mr Crocker said producers should consider the option of hand jetting from the viewpoint of practicality, cost-effectiveness and flexibility of treatment.

“If you have a treatment problem and don’t have access to a race, then this is an ideal alternative to consider.”

The units can be delivered throughout Australia and are available direct from Megajet. Orders can also be placed through local rural agencies.

Megajet also manufactures a range of four-in-one workstations, generators, welders and centrifugal pumps. The full range of equipment can be viewed at https://www.megajet.com.au/. For further information, please get in touch with Gavin Crocker either via email at [email protected] or by phoning 07 3277 6167.

HAVE YOUR SAY