CHINA’S wool industry has shared graphic photographs of contamination in Australian wool clips after industry bodies were told the problem was increasing.

CHINA’S wool industry has shared graphic photographs of contamination in Australian wool clips after industry bodies were told the problem was increasing.

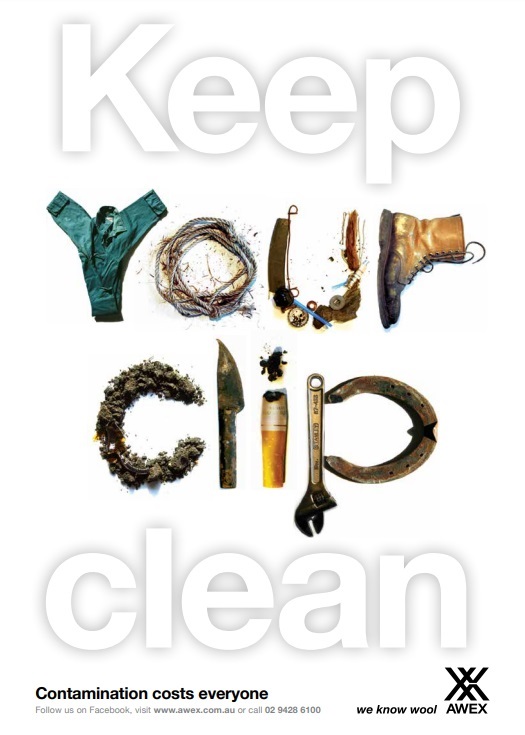

The photographs, although not yet approved for public release, illustrate that a range of items and contaminants are being found in Australian clips – including a beer can, permanent markers, cigarette lighters, a dog muzzle, gloves and other garments, twine and rope, branded fleece, bale hooks and plastic.

In one case, the photographs show how a green glove broke down to spread green dye through a wool batch after further processing.

A Nanjing Wool Market representative did not outline how much contamination of Australian wool had increased, but said a recent media release quoting Australian industry leaders would be translated and published in the Nanjing Wool Market Information weekly magazine.

“About the quality issues of Australian greasy wool & wool contamination issues, I think the Australian team of China-Australia Joint Working Group on wool will give a solution to Chinese enterprises that will be released through Nanjing Wool Market Information,” the NWM director said.

Chinese processors have not give permission for the Nanjing Wool Market to release the photographic evidence of the contamination and the Australian industry has not provided any photographs to Sheep Central despite requests.

Key to reducing contamination is prevention

Australian Wool Exchange chief executive officer Mark Grave said the key to improving or reducing contamination is prevention.

“Preventing contamination in the first place is our goal.

“By creating greater awareness about contamination amongst the wool harvesting team will only add greater value to the wool industry,” he said.

Mr Grave could not say if the problem of rising contamination can be linked to the attrition rate of professional classers in Australia.

AWEX CEO Mark Grave

“There are many contributing factors to contamination; however, the importance of the role of the classer in shed management and preparation expertise must be supported as part of the solution.

“Adequate staffing of the wool shed is an important factor in preparation as is the pre-shearing briefing to set the tone for all staff.

“It is our experience that the vast majority of wool prepared by trained and registered classers around Australia is well prepared and contaminant-free,” he said.

“Through their training, classer’s are taught to appreciate the serious impact that contamination has on a processing batch.

“Contamination is accidental and classer’s would be alarmed if a clip they classed was found with contamination.”

Mr Grave said it is always concerning when contamination is reported by Australia’s customers as it detracts from the high quality and valued work of wool classers.

When asked if AWEX has been able to establish if the contamination reported by the Chinese processors is more common in clips that are not professionally classed, Mr Grave said on the basis of the report AWEX received, it is difficult to identify the origin of the clip and whether it has been classed (or not) and by whom.

“The contamination reported by Chinese processors is predominantly a mixture of non-wool (clothing, non-wool objects etc.) and wool pack contamination.

“AWEX has requested more information from the processors so we can investigate this further,” he said.

However, the documents and photos seen by Sheep Central show that processors are keeping records detailing the date contamination is found in clips, and identifying the source property or business names, bale brand and Australian broker that handled the wool.

Mr Grave did not comment on whether AWEX would follow through to the property, broker and classer when bale identification makes tracing contamination possible, nor on whether AWEX’s e-Bale electronic bale identification system would make tracing the origin of contamination easier.

Mr Grave said receiving direct feedback from processors is critical to raising awareness of the impact contamination has on our customers.

“The solution must be a united industry solution.

“It is not just a single person’s issue but an issue for the whole of industry to address,” he said.

“AWEX will be actively communicating with trainers, classers, growers and brokers to educate and reinforce the need to ‘Keep the Clip Clean’.

“It takes years to earn the reputation Australia has for producing well prepared quality wool, but it is easy to lose. Complacency is not an option in a competitive global wool industry,” he said.

Latest in a never ending line of beat ups on classing standards. What possible damage could a beer can do? Any other alleged objects should be pulled before scouring. During nine and a half years of classing wool into a scour we never had any problems. These stories are just scare tactics to keep prices down.

With all the effort and expense that is going in to showing the world how important wool is to drive better materials into existing and new markets, it is critical not to waste it all because those doing the heavy grafting don’t care, or even know, where it ends up.

Are wool shed workers compensated for taking pride in their work? I know money doesn’t grow on trees, but if the risk is shared, so is the reward. You can’t expect to have poor working practice bring sustainable standards; you get what you pay for. Motivate wool shed staff with the knowledge that the effort they put in is so important, so critical to the output of such a valuable product.