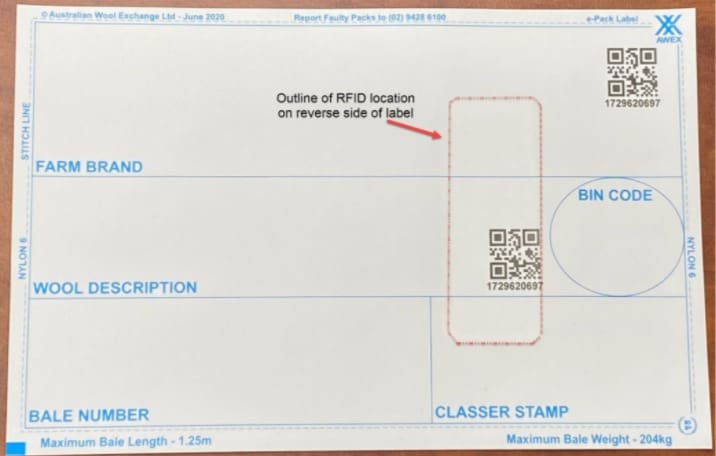

The front of an eBale bale label. Image – AWEX.

WOOL growers are being sought to take part in the latest stage of the Australian Wool Exchange’s supply chain traceability eBale project.

In a members’ project update last week, AWEX chief executive officer Mark Grave said AWEX has created the first production run of 1000 RFID/QR code-enabled bale labels.

“These labels will be deployed to create the first RFID/QR code-enabled wool packs or ePacks,” he said.

“This part of the eBale project is designed to test the full commercial production of an ePack.

“It is anticipated the 1000 ePacks will be available from February/March 2021,” Mr Grave said.

“AWEX would like to hear from growers and sellers who are interested in being part of this stage of the trial.

“The WoolClip software must be used by wool growers and classers during these trials.”

Mr Grave said the ePacks, once manufactured, will be used on-farm with the unique bale-ID and clip specification details captured using WoolClip. The information will then be sent to the warehouse/selling agent for processing.

Mr Grave said AWEX is progressing the eBale Project as a matter of priority in 2021.

“During 2020, progress on projects including eBale and WoolClip were slowed to enable AWEX to prioritise its resources to address critical industry issues including the Cyber attack on an industry IT company in February and the ongoing impact of COVID-19 restrictions on wool auctions.

“As part of its overall strategy to address ‘Traceability with Integrity’ through the wool supply chain, AWEX continued to conduct limited on farm eBale trials using remote tools to train and educate wool growers and wool harvesting staff,” he said.

He said the unique Bale-ID is captured on-farm using WoolClip and is able to be transmitted to the warehouse for downloading and use.

The eBale bale label has distinctive and unique features including:

- A distinctive BLUE printed template for easy identification in the wool shed and warehouse,

- The QR Code is printed in two locations to ensure it can be read in the event of wrinkle or line of sight obstruction,

- The two locations (see image below) were identified, through surveys at various warehouses, as the locations least likely to be wrinkled or obscured in shed and during pressing,

- The QR Codes and the RFID carry the same unique Bale-ID,

- The unique bale-ID number is printed under both QR Codes as a backup,

- The RFID, on the back of the bale label, is the prime position for the RFID to be read in transport, and at the warehouse, core line, dump and processing mill.

Mr Grave said traceability and product integrity have gained a high profile in recent years.

“It is anticipated that this will only increase in the years to come.

“The benefits of having a fully traceable product will add value from the farm gate and throughout the wool supply chain,” he said.

“The use of QR Code/RFID is expected to increase efficiencies in warehouses (domestic and internationally), thereby having the potential to reduce errors and minimize lost inventory.”

For more information contact Mark Grave on [email protected] or call (03) 9428 6110.

Source: AWEX.

HAVE YOUR SAY