Prof. Graham Gardner at the AMPC Innovation Showcase.

AUSTRALIA’S beef, sheep and pork processing industries have been transformed by six years of research and innovation by the Advanced Livestock Measurement Technologies program, according to ALMTech chief investigator, Professor Graham Gardner.

Since 2016, ALMTech has been working to develop advanced measurements of red meat quality and quantity that will enhance the Australian beef, lamb and pork industries’ ability to respond to market demands and capture value-chain price differentials.

By 2040, it is estimated that ALMTech will have generated as much as $510 million extra for the beef, lamb and pork industries in Australia.

Prof. Gardner at the inaugural Australian Meat Processor Corporation Innovation Showcase in Melbourne this week. He said ALMTech’s research has resulted in the development and adoption of several cutting-edge technologies.

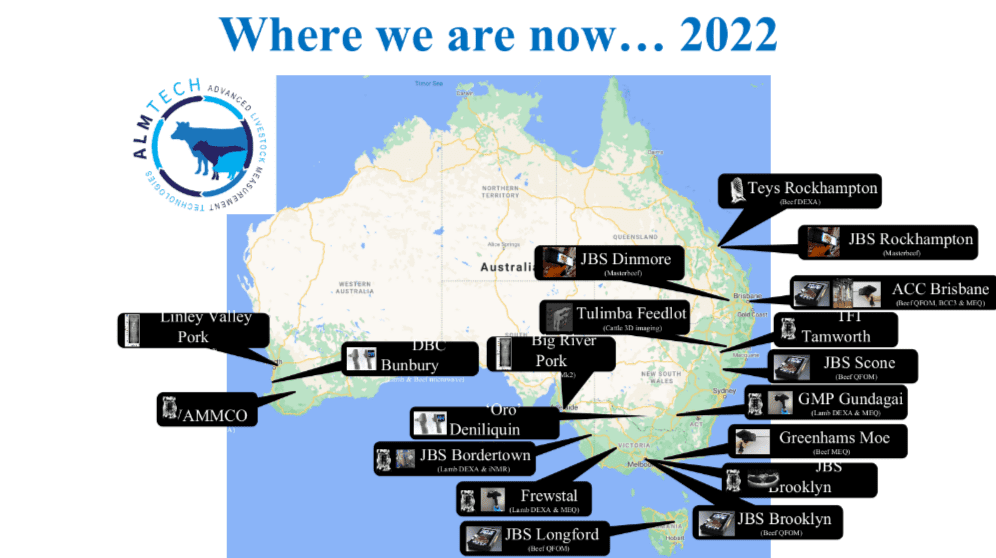

“Six years ago, we were working with just one processor, JBS Bordertown, developing the Lamb DEXA technology, now we have almost 20 industry partners and we are out there working on everything from 3D imaging and portable microwave devices to hyperspectral technologies and more,” he said.

“Every day we are helping industry get closer to that holy grail of fully objective carcase measurement and that’s exciting because we believe there is potential to capture an estimated $130 million dollars per year when producers can use our technologies to supply cattle that better meet company and consumer requirements, with similar opportunities in lamb and pork.

“Advanced measurements and feedback will enhance the transparency of trading across the livestock value chain,” Prof. Gardner said.

Traits and language for value-based beef and lamb marketing

For beef, there have been changes to the rib eye trait and the introduction of the new beef IMF trait.

Prof Gardner said the valuable thing about the new IMF trait for beef is that it enables the valuation, beyond visual grading scores, of very high marbling score product such as long-fed Wagyu.

“So this is a trait that these devices can be trained to predict which can now put a value on product going overseas, beyond the visual scores.

“On top of that we’ve already got the equations that will convert IMF into the equivalent visual score,” he said.

“The last box to tick is a debate with the MSA pathway and then the supply chain taskforce – the custodians of the MSA model – who allow an IMF value to be converted into a visual MSA marbling score to populate the MSA model and tell you what the eating quality is for beef.”

Prof. Gardner said these issues were “sorted” with lamb, “because IMF is the trait in the MSA model” with the new IMF% and CT Lean% traits, that can now be measured by accredited devices.

Prof. Gardner said for lamb, there are now accredited measurement devices in plants – DEXA, fat and IMF measuring devices – with new language for whole carcase composition and IMF traits, rolling out the Meat Standards Australia model.

“So before the language existed, we couldn’t actually roll out the MSA model because there were no devices measure the traits and the traits themselves had no industry language that they could be accredited against.”

Prof Gardner said anyone who can now measure lean meat yield with a GR knife or a DEXA, and with an accredited device to measure IMF is “good to go” to market MSA lamb. DEXA and SOMA (1.5-8 IMF%) was AUSMEAT accredited two weeks ago, and the MEQ Probe (1.7%-6.5 IMF%) prior to that. DEXA is now accredited for whole carcase bone, fat and muscle percentage across all weight ranges.

Prof. Gardner’s session at the AMPC Innovation Showcase included presentations from WAMMCO supply development manager Robert Davidson and Gundagai Meat Processors chief executive officer Will Barton on their use of DEXA and MEQ Probe.

Both companies have been crucial supporters of ALMTech research, hosting numerous trials to adapt these technologies for use in processing plants.

“As researchers it’s our dream to see the research and development that we do go out and impact industries in the real world and that’s what we are seeing happening,” Prof. Gardner said.

“It’s an essential part of the innovation process that industry trials new technology and shares their experiences so it’s great to have the speakers from WAMMCO and Gundagai Meat Processors on board to explain how their respective businesses are using and benefitting from these technologies.”

The ALMTech project is supported by funding from the Australian Government Department of Agriculture, Fisheries & Forestry as part of its Rural R&D for Profit Programme, in partnership with R&D corporations, including the AMPC, commercial companies, state departments and universities.

Source: ALMTech.

HAVE YOUR SAY